Category

Contact us

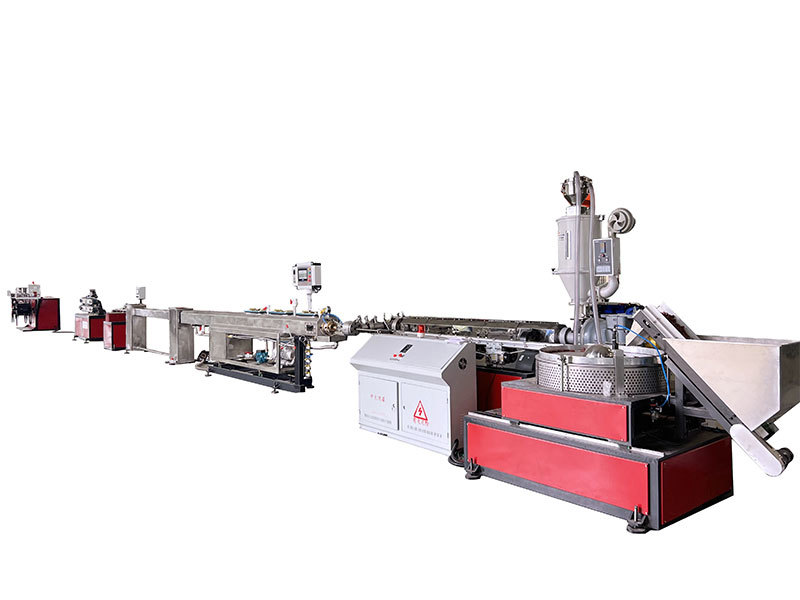

Inner flat emitter drip irrigation tape production line

Key words

Inner flat emitter drip irrigati

Details

Product:

|

Name: |

Tape diameter(mm) |

thickness(mm) |

Dripper space(cm) |

|

Drip tape |

16mm |

0.16-0.4mm |

10-100cm |

Wroking condition:

|

humidity |

0-40℃ |

|

Power source |

3 phase 380v, 50Hz |

|

Installation power |

About 120kw |

|

Cooling water |

≤15℃ ≥0.3Mpa ~100L/min |

|

Compressor air |

5m3/h 0.4-0.6Mpa |

|

size |

30*3*2.6m(l*w*h) |

|

Line speed |

0-320m/min |

Production line compositon

|

Name |

|

Every part name |

No. |

|

Inner flat emitter drip irrigation tape production line

|

1 |

Dripper sorting and inserting systerm |

1 |

|

2 |

Automatic material feeding and drying system |

1 |

|

|

3 |

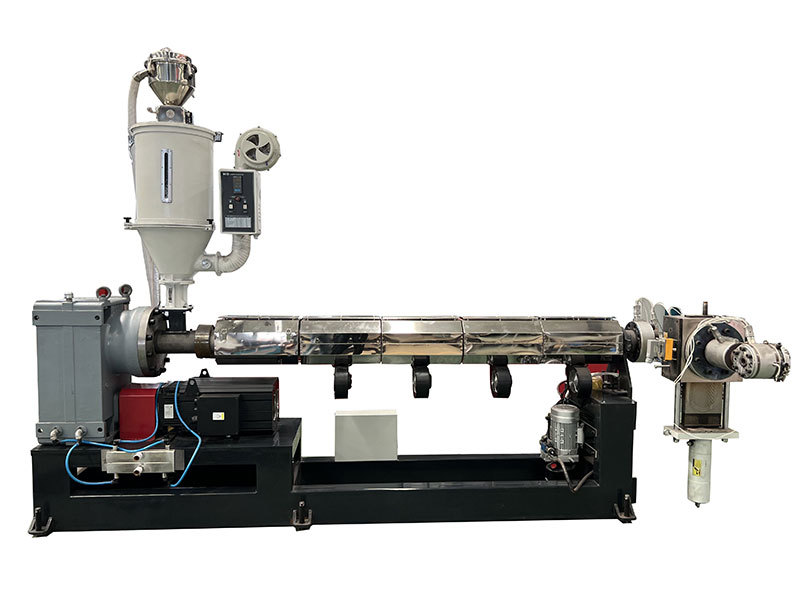

SJ-75×38/1 single screw extruder |

1 |

|

|

4 |

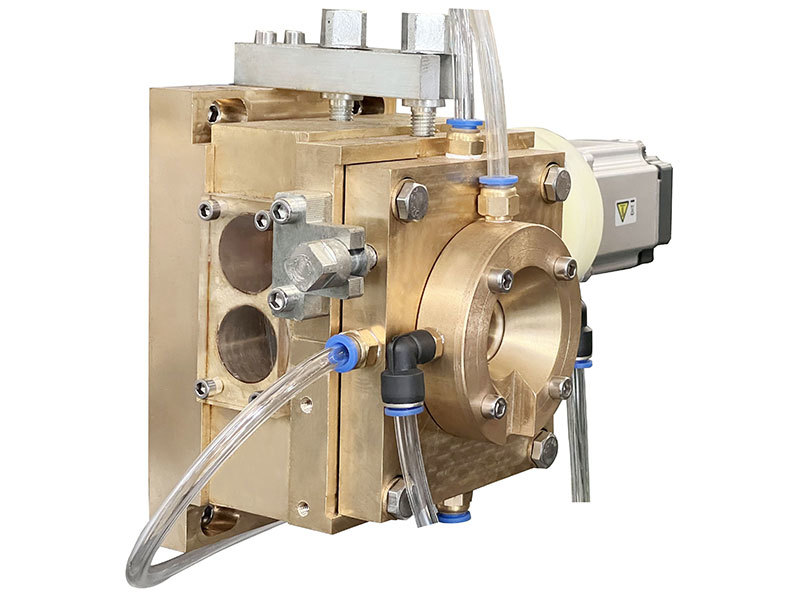

Die-head |

1 |

|

|

5 |

Vacuum sizing tank |

1 |

|

|

6 |

Cooling water tank |

1 |

|

|

7 |

Haul off and punching systerm |

1 |

|

|

8 |

Winding machine |

1 |

|

|

9 |

Electric cabinet |

1 |

|

|

10 |

chiller |

1 |

Main technical parameter:

sorting and inserting system:

þ Infrared photoelectric sensor accurately controls the automatic feeding of the flat dripper

þ Ø1500mm sorting and inserting speed 2300pcs/min

High efficiency extruder:

þ high output,low energy consumption and low noise

þ After quenching and tempering and nitriding heat treatment, the screw barrel has the characteristics of high temperature resistance, wear resistance, corrosion resistance and high strength, which greatly increases the service life; Reasonable and unique design of plasticizing section makes the surface of products smooth and glossy.

PLC control system:

þ The whole machine adopts high-performance PLC man-machine interface control system, and the operation process is convenient and easy to understand.

Vacuum sizing and cooling system:

þ Sizing system: a variety of alloys synthesize high-strength wear-resistant brass, which is easy to adjust.

þ Vacuum system: advanced pipeline layout design, good vacuum sealing and better cooling effect.

Haul off and punching system

þ Tractor: it adopts high-speed belt type pneumatic regulation traction

þ Punching part: four groups of High-speed Servo punching, and the punching speed can reach 3000 times / min

þ Detection system: Sony high-speed camera monitors the punching effect of each hole in real time; The system will give an alarm automatically if there is missing or deviation, and can set the punching qualified rate by itself. If it exceeds the range, the system will give an alarm automatically and the winding will stop automatically, which is convenient for workers to detect.

High speed winding machine:

þ Automatic cutting, automatic roll changing

þ Meter setting: 1000-2000m / roll

þ Add video synchronization detection

-

- Inner flat emitter drip irrigati

Online consultation

Please describe in detail the questions you need to consult, and we will arrange for a specialist to contact you in time

More Products

More Products